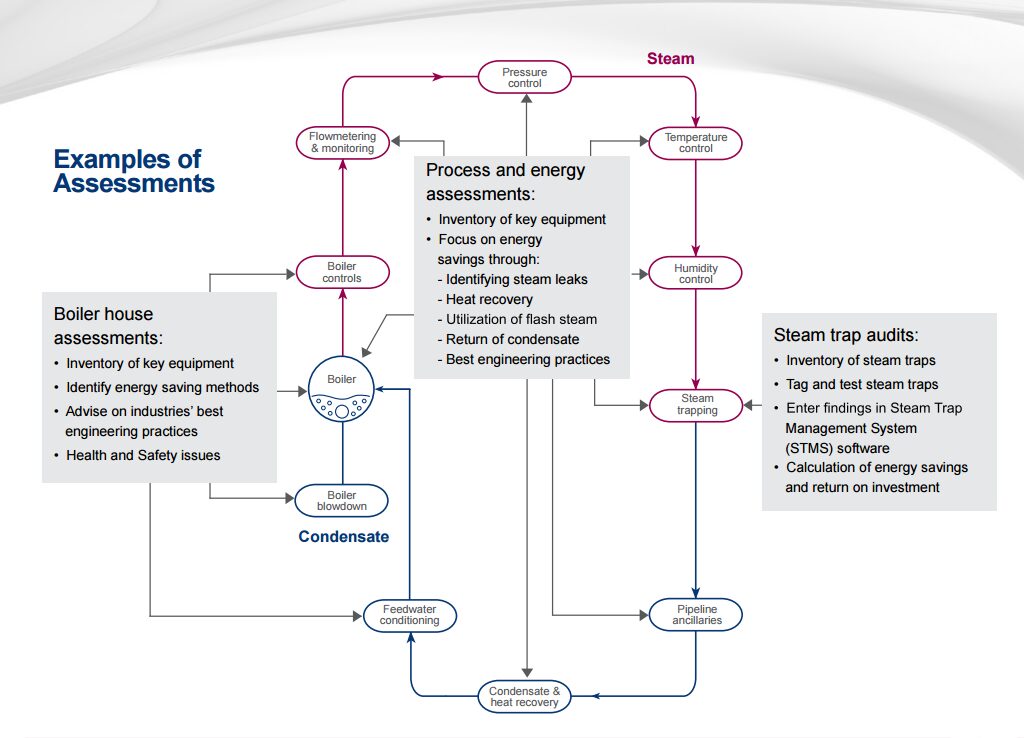

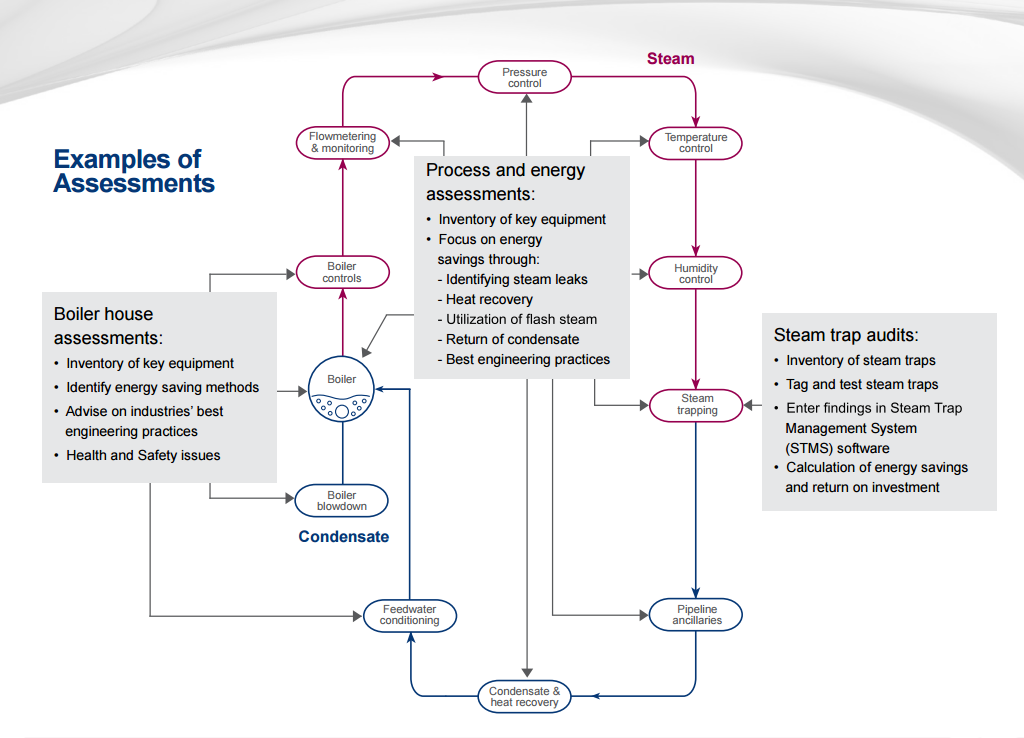

Modern day organizations that operate steam systems face tough challenges, from tightening of safety/environmental legislation to shortages of specialist skills. An audit is tailored to your process application and budget availability. An audit can include the complete steam distribution loop, starting with the boiler right through to process applications and condensate return. Each audit is designed to your particular requirements and is conducted by experienced engineers. Following the on-site work, a detailed and comprehensive report is produced and presented back to you.

The audit report will highlight recommended actions with calculations of the potential return on investment that is likely to be achieved. The report will include an objective analysis to help you decide what further action to take. The full scope for improvement of the steam system is summarized in the report’s Executive Summary, which lists the recommended action points in order of priority.

Typical areas covered by a Steam System Audit report include:

• Achievable energy savings based on actual operating conditions

• Recommended equipment to achieve energy savings with return on investment

• Identification of productivity improvements, for example through faster warm up time or improved heat transfer

• Full Steam Trap Survey and report

• Potential areas for improved product quality (where applicable)

• Planned preventative maintenance schedule (if required)

• Advice on good engineering practice

• Site drawings (if specified)

• Photographic evidence (where applicable)

FOR MORE INFORMATION: Please contact your local MECO representative to understand more on how we can help optimize your plant efficiencies.

*Article and graphic courtesy of: