FIRE PUMP SYSTEMS

Electric Motor Driven Horizontal Split Case Fire Pump (1000 GPM @ 100 PSI) skid-mounted system to include 6″ suction control valve, 6″ flow meter test loop, 6″ manual bypass, and jockey pump system, pre-piped and pre-wired on an open I-beam base.

INDUSTRIAL / COMMERCIAL PROCESS SKIDS

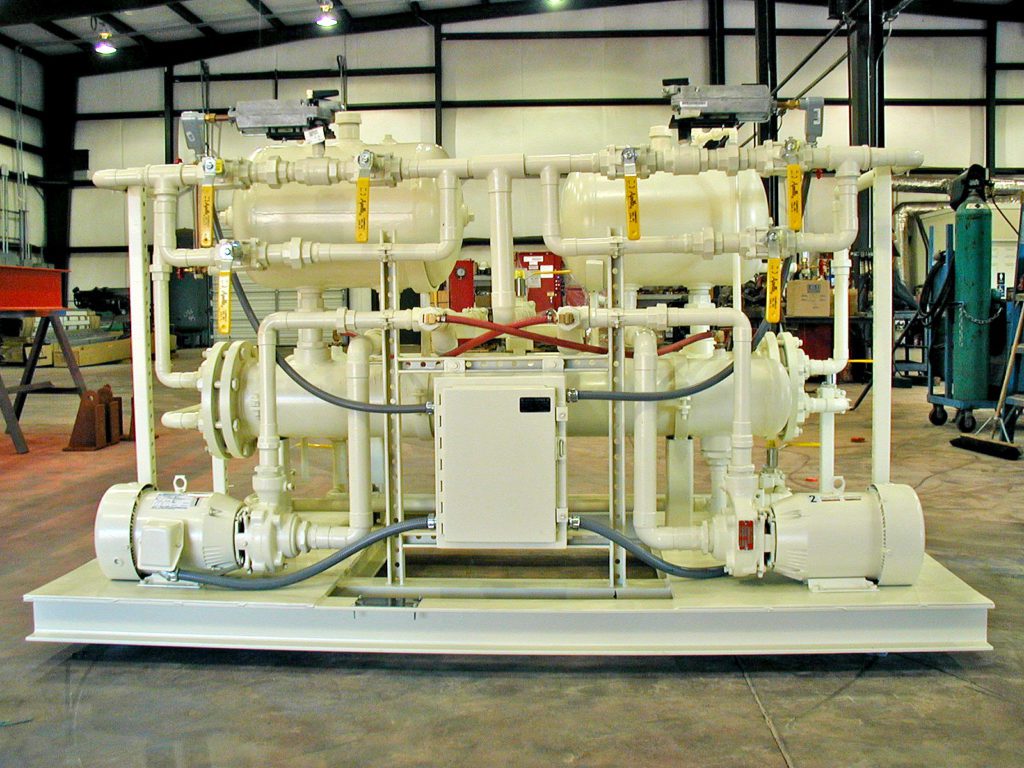

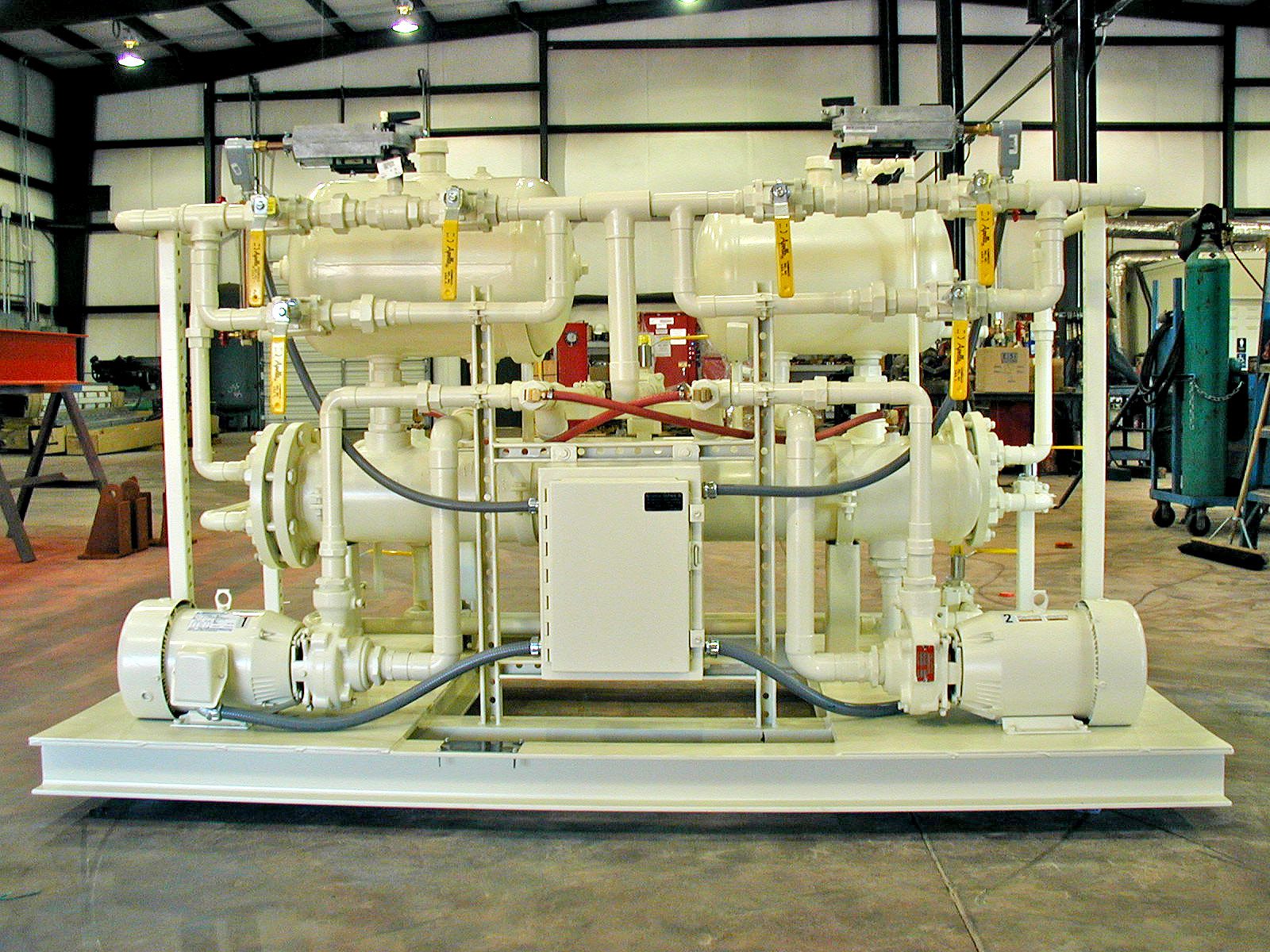

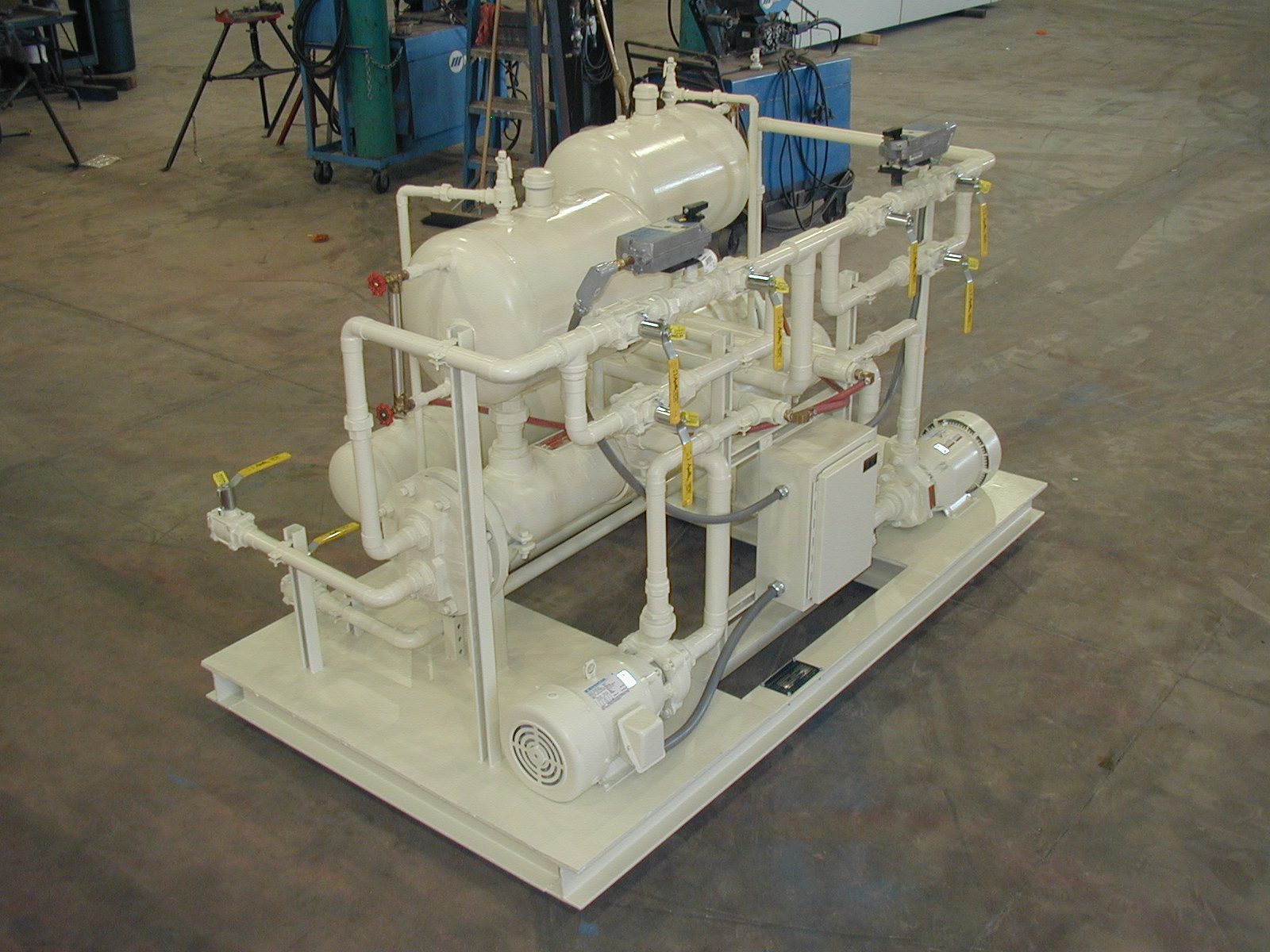

Duplex Heat Transfer Skid System for hot water loop with end-suction centrifugal pumps, suction air separator, suction triple-duty valves, expansion tank and steam heater with steam control loop and valve, control panel all pre-piped and wired and mounted on a fabricated steel base.

MUNICIPAL SKIDS

Duplex Seal Water System with stainless steel air break reservoir with float switch, solenoid make up valve, duplex regenerative turbine-type seal water pumps with motors, stainless steel piping, control panel, all pre-piped and wired on a fabricated stainless steel base.

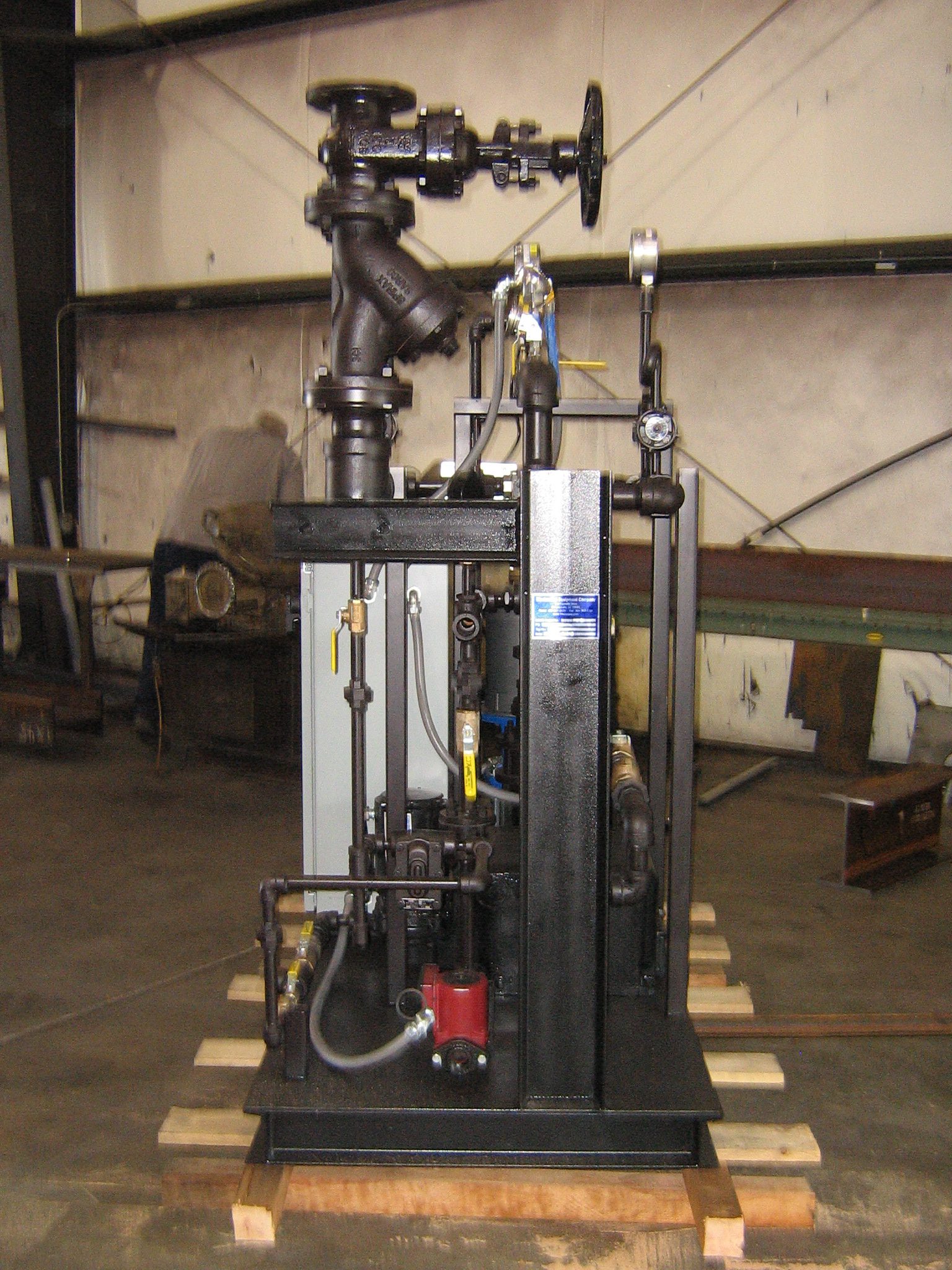

FIRE PUMP SYSTEMS

|

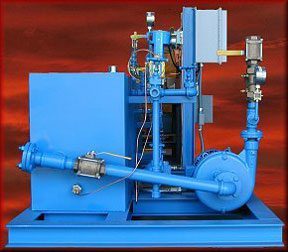

Fire Pump Package P-7564

Electric Motor-Driven Horizontal Split Case Fire Pump System (1250 GPM @ 100 PSIG), skid-mounted to include an 8″ flow meter test loop, 8″ manual bypass, jockey pump system all prepiped and wired on an I-beam base.

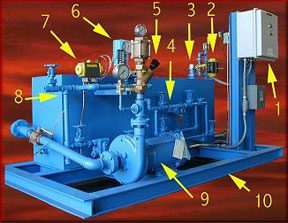

Fire Pump Skid J-3897

Electric Motor-Driven Horizontal Split Case Fire Pump System (1250 GPM @ 100 PSIG), skid-mounted to include an 8″ flow meter test loop, 8″ manual bypass, jockey pump system all pre-piped and wired on an I-beam base.

- 1. UL Listed / FM approved Aurora Fire Pump with electric motor

- 2. Aurora Multi-Stage vertical in-line Jockey Pump

- 3. Bypass Loop

- 4. FM Approved Diaphragm Actuated suction control valve

- 5. Heavy Duty 10″ Steel I-Beam frame

- 6. UL Listed / FM Approved NEMA 2 fire pump control panel

- 7. UL Listed / FM Approved NEMA 2 jockey pump control panel

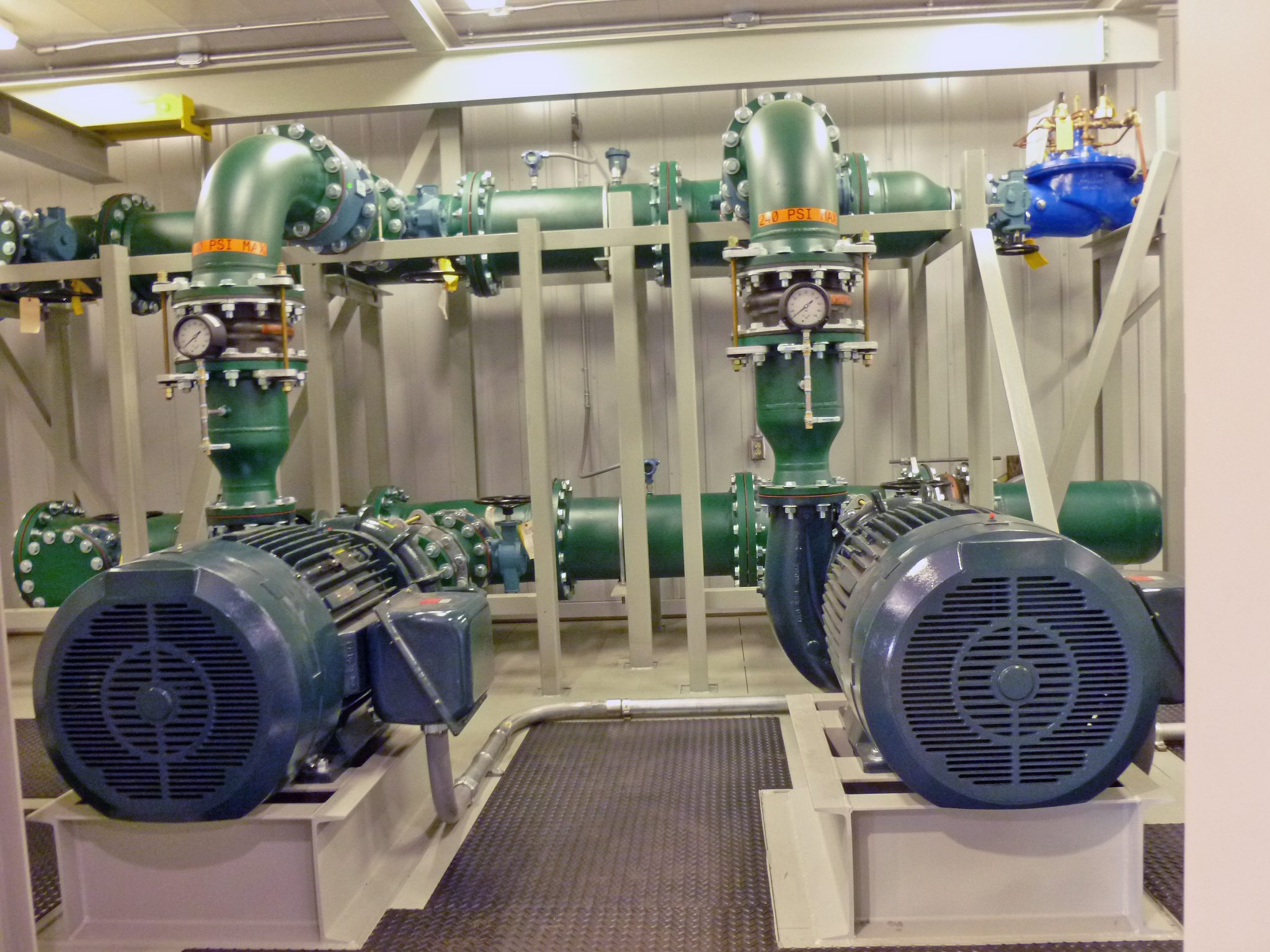

Fire Pump System in Building with Tank J-5954

Electric Horizontal Split Case Fire Pump (500 GPM @ 100 PSI) packaged skid with 4″ altitude valve for automatic tank fill. Inside a 10?-8? W x 17?-4? L x 9?-6? H metal building with: 6? double door, exhaust fan, intake louver, unit heater, interior lights, exterior light with photocell, emergency light, and exterior rotating beacon.

- 1. UL Listed / FM approved Aurora Fire Pump with electric motor

- 2. 6” Flow Meter

- 3. Single Point Electrical Service Connection with Prewired Power

Distribution System - 4. Alarms and Supervisory Switches rewired to Common Junction Box

- 5. Columbian TecTank Bolted Steel NFPA 22 Compliant Fire Water Storage Tank

Fire Pump System J-7557

Mt. Pleasant Fire and Police Training Center Water System

Featured in the Charleston Regional Business Journal

5404 Seewee Road – Awendaw, South Carolina

Owner: Town of Mount Pleasant

General contractor: A.C. Schultes of Carolina Inc., Wallace, N.C.

Engineer: E.M. Seabrook Jr. Inc., Mount Pleasant

Estimated completion date: Phase 2 (water system): winter 2012; Phase 3 (project) calendar year 2012

Estimated total cost: $476,037 – http://www.charlestonbusiness.com

The project consists of the installation of a well pump, nominal 20,000-gallon atmospheric storage tank for fire pump supply,automatic 1,000-gpm fire pump, 10,000-gallon pressure storage tank, 8” distribution piping for fire training system, fire hydrants,dry hydrants, and 2” distribution piping for future classroom and training facilities.

Hot Water Circulating Tank & Pump

- 1. NEMA 4X Control Panel

- 2. Makeup Water Fill Valve

- 3. Level Probe with Stilling Well

- 4. High Performance Steam Trap

- 5. Balancing valve for precise flow adjustment

- 6. Self-regulating temperature control valve with temp. indication

- 7. Steam shutoff valve (interlocked with pump run)

- 8. Drip leg in front of control valve with trap

- 9. Circulation pump

- 10. Heavy Duty 4″ I-Beam Frame

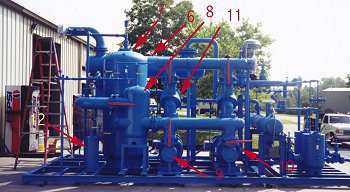

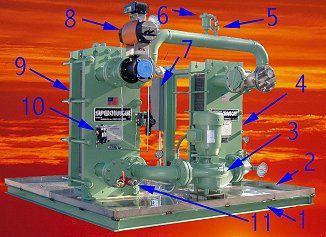

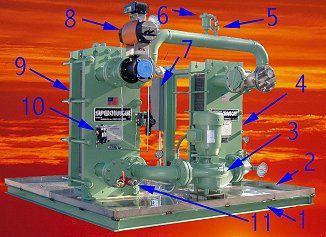

Steam Heating Skid

A skid for heating a chemical bath with steam, using two plate and frame heat exchangers to isolate the chemical bath from the high temperature steam. There is a closed loop water circulation system that circulates water through one heat exchanger where it is heated by steam. The water is then circulated through the other heat exchanger to heat the chemical bath. This system gives the user all the benefits of steam heating while using the closed water loop to avoid having the chemical bath exposed to the high steam temperatures.

- 1. Channel Iron Frame

- 2. SS Drip Pan

- 3. Aurora Water Loop Circulation Pump

- 4. Tranter Plate and Frame heat exchanger used to heat chemical bath

with hot water. - 5. Pressure safety relief valve on water loop

- 6. APCO Air release valve on water loop

- 7. Combination disconnect starter for circulation pump

- 8. Steam Control Valve

- 9. Tranter Plate and Frame heat exchanger used to water with steam

- 10. I-P for control valve

- 11. High performance steam trap

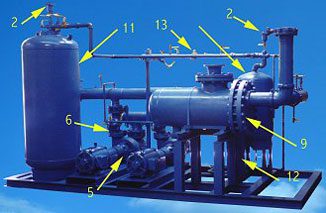

Condensate Return Unit

- 1. ASME Design dished head carbon steel receiver

- 2. Oversize vent and inlet connections

- 3. Conductive probe type level control with SS probes and stilling well

- 4. Oversize vent and inlet connections

- 5. Gauge glass on receiver

- 6. 3″ oversized pump suction piping with flanged gate valves and strainer

- 7. Low NPSH condensate pump

- 8. 4″ I-beam frame

- 9. NEMA 3R duplex control panel with H-O-A switches, pump alternator,

with lead + lag pump control

HVAC Heat Transfer System

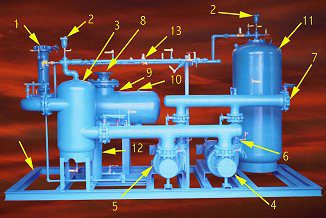

HVAC Heat Transfer Skid

- 1. Process water inlet

- 2. Air release valve

- 3. Air Separator

- 4. Suction Diffuser

- 5. Centrifugal pump

- 6. Triple Duty Valve

- 7. Process water outlet

- 8. Steam Inlet

- 9. Shell and Tube Heat Exchanger

- 10. Vacuum Breaker

- 11. Expansion Tank

- 12. Chemical Shot Feeder

- 13. Make up water assembly including regulator & bypass

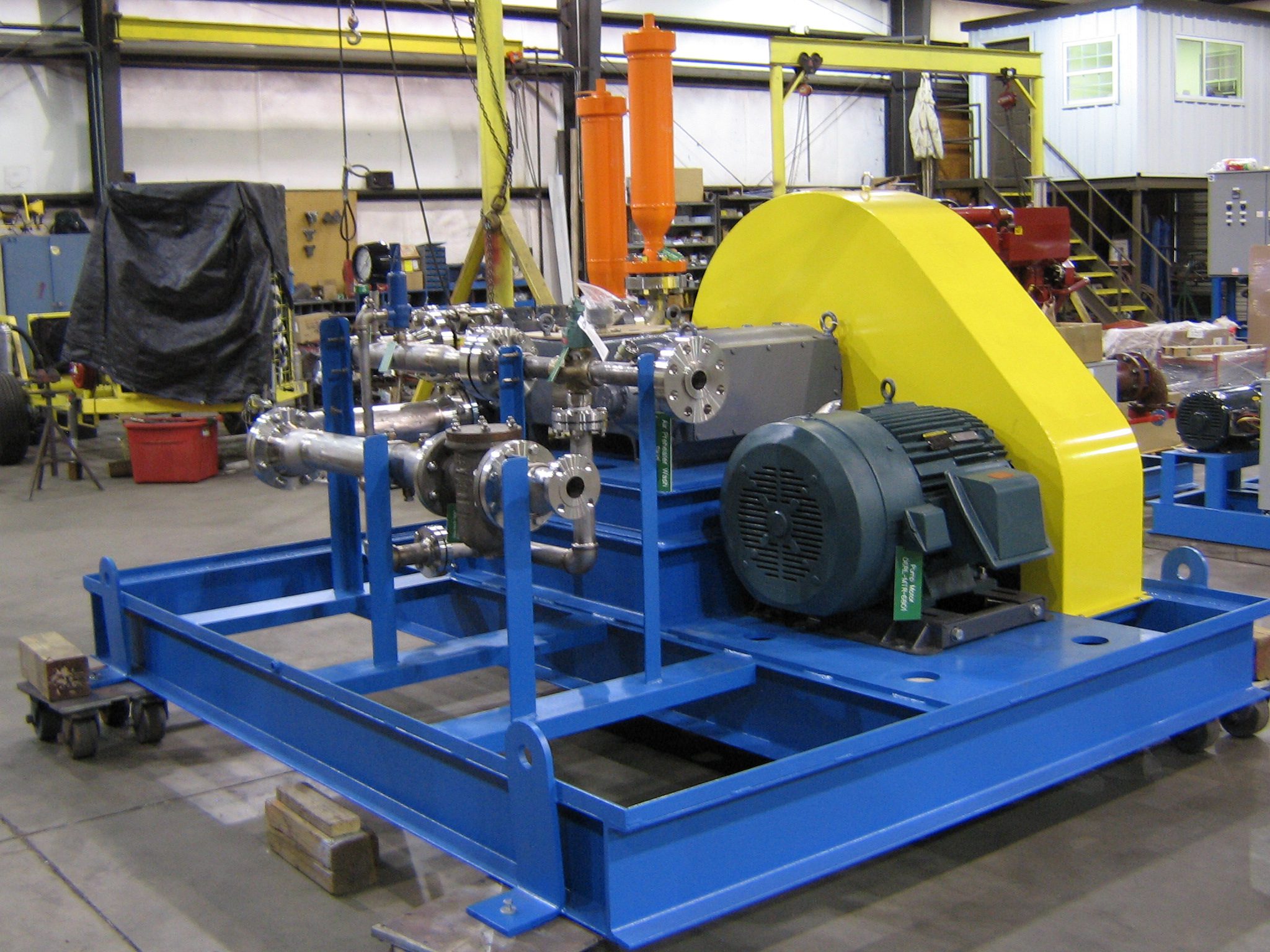

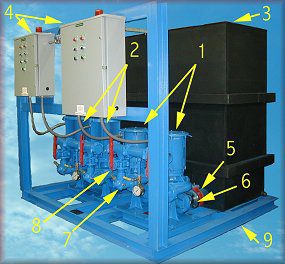

Chilled Water Pumping Skid

For Plastics Molding Company

Integrated skid for an open loop chilled water system complete with pumps controls and insulated tank

- 1. Chiller Pumps

- 2. Chilled Water Process Supply Pumps

- 3. Insulated tank, Internal baffle between hot side and cold side, level

controls, and fill valve - 4. NEMA 3R control panels, Duplex alternating type, high water alarm,

low water alarm, H-O-A switch for each pump, Lead pump selector

switch, pump run indication light - 5. Suction Shut off valve

- 6. Suction Shut off valve

- 7. Triple Duty valve on pump discharge, (Flow measurement /

Flow regulation, Flow shutoff, and check valve) - 8. Shutoff valve for each pump

- 9. Rigid I-Beam Frame